Composite Enclosures for Sensitive Electronics | Trelleborg

Onboard electrical systems are present in any modern means of transport, and they have become critical in ensuring the safe and effective operation of vehicles. Unfortunately, they can be susceptible to harmful electromagnetic occurrences causing significant difficulties up to, and including, total failures.

Damaging events such as lightning, high-power radio frequencies (HPRF), high-power microwaves (HPM), and electromagnetic pulses (EMP) can result in permanent and/or catastrophic damage to electronic circuits and infrastructure.

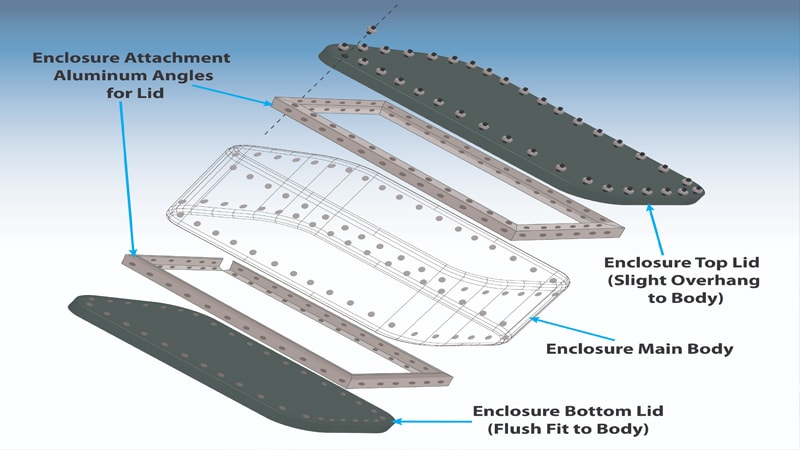

To help protect against this damage, many industries take advantage of housing for electronics that block external electrical fields by isolating sensitive components. However, these protections often come with tradeoffs.

Metal enclosures are heavy and can hinder a car’s or aircraft’s ability to meet weight demands. An innovative solution is needed to bring protection to electronics while minimizing the weight impact of the materials used. High-performance composites are well-suited to fit this need and bring their own advantages to the table as well. Teaming with SURVICE Engineering, Automated Dynamics has developed a composite enclosure that reduces weight while equaling the level of protection of current designs.

The Advantage of Composites

- Shielding protection and durability are maintained while drastically reduced weight is realized

- Greater than 70% weight savings over metallic enclosures such as aluminum

- Resistant to chemicals and fluids, CBRN effects, and decontamination exposure

- Use of Automated Fiber Placement for manufacturing allows for simple and efficient scalability

- AFP provides greater customization to fit unique needs

- Sufficient shielding effectiveness to support all applicable MIL-STD-461, 464, and 2169B requirements

Testing Results From SURVICE and National Technical Systems

“EM shielding effectiveness testing was conducted on the SURVICE developed composite enclosure at the National Technical Systems (NTS) (formerly Wyle Laboratories) in 2014.

For this testing, the enclosure was completely sealed, with the exception of provisions for the antenna and cable. A subminiature version A (SMA) connector was mounted on the side of the enclosure box, which allowed an RF tight connection for the coaxial cables between the antenna inside the enclosure and receiving equipment outside the enclosure.

When compared to the test results for an aluminum enclosure of the same shape and size (as well as a baseline shielding effectiveness of 60 dB against all frequencies), the composite enclosure test results clearly demonstrated that the shielding effectiveness of the composite enclosure, although much lighter than the aluminum baseline version, provides equivalent EM protection. In addition, due to the material and process used in composite manufacturing, developers recognize the potential to tailor the shielding effectiveness of the composite enclosure to develop a balance between weight, structural capability, and shielding.” – SURVICE Engineering Company

For more information, contact:

Gabriel Benarroch, Aerospace Business Development Manager

518.377.6471 ext.212| Email Gabriel