Color-coordinated

All aircraft interiors have gaps, seams and spaces that are unsightly or present a potential hazard to air travelers. In the average plane, an estimated 700 to 900 kilograms of thermoplastic and elastomer extrusions fill, cover and manage these areas. Designed to ensure safety in the cabin and cockpit as well as to protect the plane’s interior structure from damage due to passenger traffic, extrusions and injection molded parts also provide a pleasant aesthetic experience for the passenger.

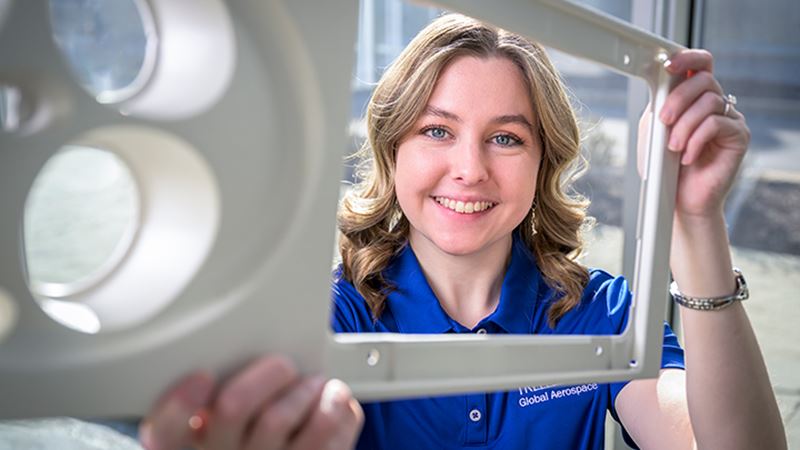

“When I walk onto a plane, I am so proud of the components we provide for aircraft interiors,” says Sidney Basham, an applications engineer with Trelleborg’s aerospace team who helps develop and optimize extruded thermoplastic and injection molded components.

“Our products are visible everywhere you look,” she says. “I love the fact that I can sit in my seat and see lots of the things we supply, from parts on the overhead bins to the thresholds on the floor and the window shades, as well as the covering strips between the panels at my side. I do feel a little nerdy, though. In the last plane I was on, I even knew the Boeing profile number of the seat tracks my chair ran on.”

Making sure that colors are consistent throughout a plane and from plane to plane is important in upholding strict airline branding. To this end, Trelleborg is approved for color matching by major aircraft manufacturers, including Boeing and Airbus.

“It’s a sobering fact that a fire that is allowed to spread through an aircraft’s interior could become uncontrollable in just eight to 10 minutes,” says Basham. “That’s why our interior components go through stringent, internationally recognized testing procedures related to flammability, smoke and toxicity. Flame-retardant and flame-resistant materials aid in preventing catastrophic emergencies and significantly mitigate harm to passengers if fires occur.”

Although interior components may look simple, the processes that go into producing them certainly are not. Basham explains the challenges Trelleborg faces in achieving visually acceptable extrusions. “We are working with very specialized materials and to tight manufacturing tolerances,” she says. “Producing extrusions requires intricate extrusion dies and calibration equipment. Raw materials are stored to meet specific requirements, and the compounds that are fed into extruders must be prepared carefully. As extruded profiles cool, temperatures require meticulous monitoring and controls to maintain geometry and desirable surface finish. Since nearly every profile is visible, there is no room for defects on finished products.”

Light lenses, which require a level of transparency as well as a colorful hue, are extremely demanding to fabricate. “Transparency is difficult to measure and even more difficult to describe during development, so additional collaboration is necessary between the customer, Trelleborg and our material supplier network,” explains Basham. “The raw material for these transparent components is typically a polycarbonate, which usually has some level of transparency after processing and then we add colorant to it. The end product will still be the shade of a specified interior color, but it will be translucent.”

One of the most technically problematic injection molded parts Trelleborg produces is also one that many people find amusing. “We make toilet seat and lid assemblies for a lot of planes,” says Basham.

“Due to extremely high visibility to the passenger, potential bacterial buildup and frequent cleaning with harsh chemicals, they need to have one of the best surface finishes of any interior component. There can’t be any color defects, which is quite tricky with large, flat injection molded parts as the resin has so far to travel. We’ve invested research and development time into making improvements on tooling to achieve and go beyond required standards.”

As for the future, Basham says Trelleborg’s aim is to expand its overallcolor portfolio and to continually add more Boeing- and Airbus-approved colors. “We want to have as many colors as possible, so they are already approved when our customersrequire them,” she says.

For more information, please visit: Seals