Transforming lateral pipe rehabilitation with Light-Curing technology

Lateral drainpipes, which connect individual properties to public sewer systems, play a vital role in wastewater management. Over time, these pipes often deteriorate due to factors such as infiltration, exfiltration, root intrusion, or corrosion. This degradation compromises the structural integrity of the pipes and poses risks to public health, surrounding infrastructure, and treatment facilities. As municipalities increasingly turn to advanced technologies for rehabilitation, cured-in-place pipe (CIPP) technology has emerged as a leading trenchless solution for repairing lateral pipes efficiently and cost-effectively.

The need for lateral pipe rehabilitation

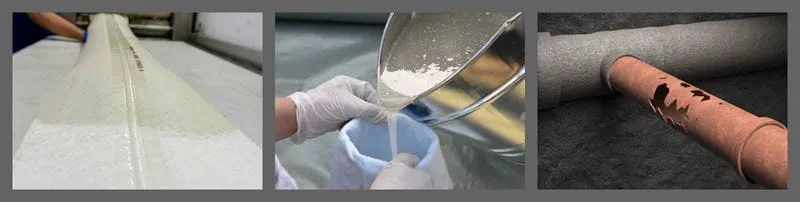

CIPP technology is a trenchless method of rehabilitating damaged pipes by inserting a liner saturated with resin into the existing pipe. The liner is then inflated to conform to the pipe’s shape and cured to create a leak-tight, durable new pipe within the old one. The curing process can be accomplished through various methods, including thermal, ambient, and light curing.

The rise of Light-Cured CIPP

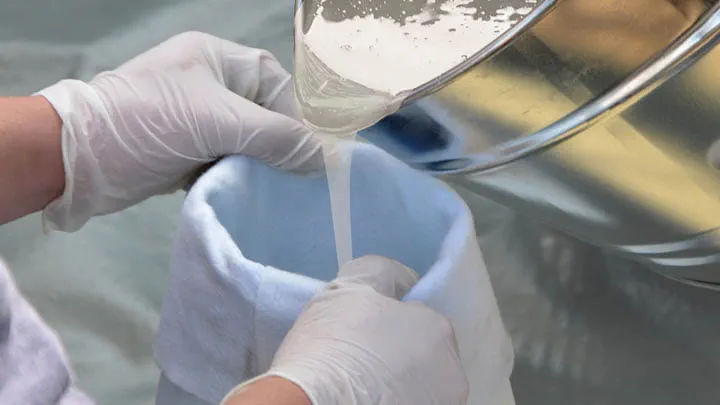

Among the curing options, light-curing has gained significant popularity for its efficiency and quality control advantages. Light-cured resins can be wet-out in controlled environments, allowing for better management of resin application (no mixing, 1 component) and liner preparation. This method requires less time and space at the installation site compared to traditional thermal curing.

A key advantage of light-curing is the ability to pause and restart the curing process as needed. If an issue arises during installation, operators can simply turn off the lights, address the problem, and resume curing—something that’s not possible with thermal curing. Additionally, light-curing equipment inserted inside the liner allows for real-time monitoring of video, pressure, and temperature data, ensuring superior quality control throughout the process.

Limitations of traditional resins

Historically, unsaturated polyester and vinyl ester (UP and VE) resins have been the standard for CIPP applications. However, these materials present several challenges. UP and VE resins tend to shrink significantly upon curing, leading to the formation of annular gaps between the liner and host pipe. These gaps can allow water and effluent flow, enabling root growth and compromising the pipe’s watertight integrity.A Superior alternative

To overcome the limitations of traditional resins, Urethane Acrylate (UA) resins have been developed. These resins offer numerous advantages, including excellent bonding to host pipes, minimal shrinkage, and high impermeability. Independent testing has demonstrated pull-out strengths of up to 763 PSI, depending on the host pipe material, which ensures a strong and durable bond.

UA resins are also environmentally friendly, as they do not contain styrene. They can be shipped and stored safely without requiring extensive VOC mitigation measures, making them a safer, more sustainable choice.

The Future of lateral Pipe pehabilitation

The adoption of light-curing technology combined with UA resins is transforming the landscape of lateral pipe rehabilitation. This advanced approach not only addresses the limitations of traditional methods but also delivers superior results with reduced environmental impact. Municipalities and property owners alike stand to benefit from faster, more reliable installations and longer-lasting rehabilitations.As the demand for sustainable and efficient infrastructure solutions continues to grow, light-cured CIPP with UA resins is set to become the gold standard for lateral pipe rehabilitation, ensuring cleaner, safer, and more resilient wastewater networks.

For more information contact: